Core Technology

Ultra HD Video

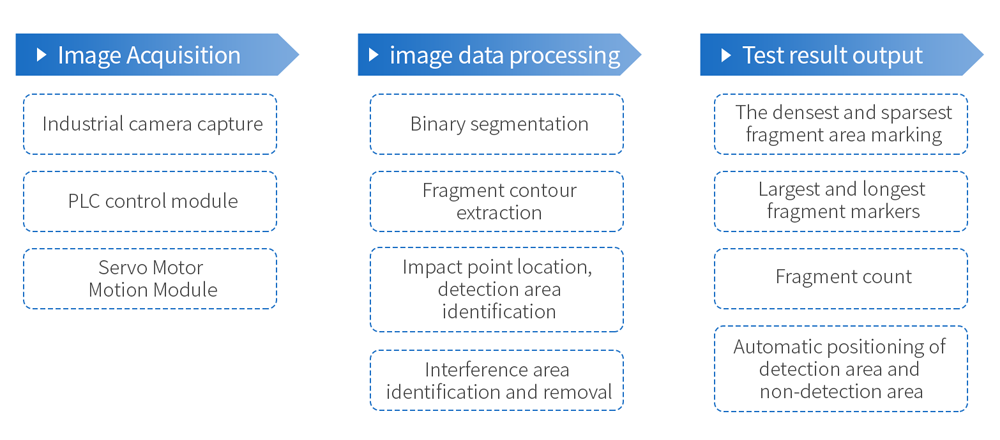

Smart Manufacturing

IVCloud

Retouching APP

About

.png)